We Supply, Design, Engineering, Installation & Commissioning of the following Units

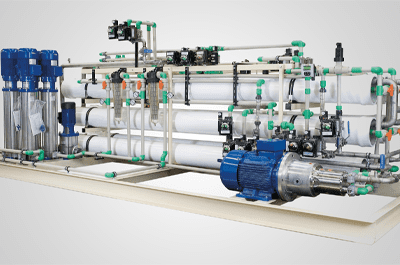

Brackish water consists of more dissolved solids than tap water but has lower salinity than seawater and usually arises from underground water sources. Impurities in the water make it difficult to use in many applications. For instance, brackish well water (if not purified) can significantly damage agriculture, houses, and other applications. Brackish reverse osmosis systems are designed to function over 200 psi and require more energy through greater pressure pumps. The TDS level of brackish water typically falls between 1,000 ppm to 10,000 ppm. The system is designed to handle higher pressure than tap water RO.

Demineralization is the removal of dissolved minerals that form salts when water is evaporated. These salts have corrosive properties and must be removed for industrial processes so that they don’t damage equipment, such as high-pressure boilers. The performance of demineralizer systems is dependent on influent water chemistry, system design (co-flow or counter-flow), type of resin installed and regenerate type and concentration.

Nanofiltration membranes are utilized for the filtration of water with low total dissolved solids (TDS) to eradicate organic substances and soften water. Nanofiltration is usable in many water and wastewater treatment industries for the practical removal of ions and organic material. It has also been adopted as a pretreatment to RO. Other than water purification, nanofiltration membranes are also used to manufacture food & beverages and pharmaceuticals.

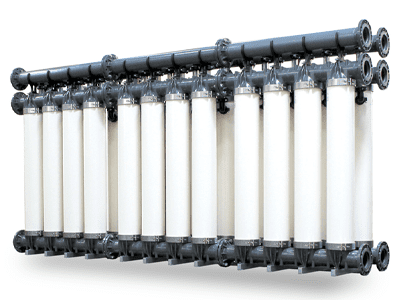

Ultrafiltration systems utilize hollow membrane fibers to eliminate suspended solids, bacteria, viruses, and pathogens from the feed water. Pumps send the treated water through microscopic pores, which act as a physical barrier that only allows filtrates to pass through them. Ultrafiltration strainers are used next to remove solids such as weeds and plastics from the filtered water before it enters the UF system. Ultrafiltration plants have been extremely useful in water and wastewater treatment by continuously providing excellent results. After UF treatment, the water can be sent to a reverse osmosis system for further purification or can be used supplied for immediate public usage.

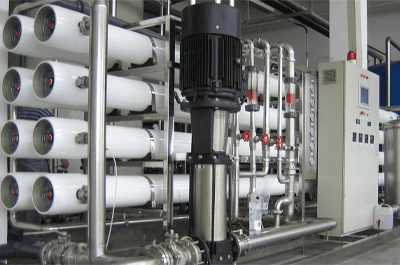

Membrane cleaning systems are designed to clean the membranes of any reverse osmosis, nanofiltration, and ultrafiltration system without dismantling them from the membrane system. For example, CIP skids are attached to the reverse osmosis membrane array, and cleansing mixtures are spread throughout the membrane components.

Industrial water filters are utilized to eradicate impurities from water in industrial applications. The pores in these water filters are small enough to allow water to seep through, but not suspended solids that contaminate the water. Various industrial water filters are built for different usage. They can be used for various applications such as water pre-treatment for reverse osmosis systems, nanofiltration, ultraviolet sterilizers, ion exchange, and ultrafiltration systems.

The cartridge filter housing is generally utilized for cleaning or polishing in any process industry. Cartridge filter housing works by evenly distributing unfiltered water around the cartridges, from the outside to the inside. Suspended solids are captured from the outside for an easy expulsion, and the filtered water exits through the outlet pipe.

The industrial water softener system is specific ion exchangers designed to remove ions that are positively charged. Softeners mainly remove calcium (Ca2+) and magnesium (Mg2+) ions. Calcium and magnesium are often referred to as “hardness minerals.” Softeners are sometimes even applied to remove iron from water. Commercial water softeners collect hardness minerals within its conditioning tank and flush them away to drain from time to time. When an ion exchanger is applied for water softening, it will replace the calcium and magnesium ions in the water with other ions, for instance, sodium or potassium. The exchanger ions are added to the ion exchanger reservoir as sodium and potassium salts (NaCl and KCl).

Mobile water treatment and purification plants are designed to cover an emergency, temporary solutions such as construction sites or long-term water treatment requirements. These portable systems are installed inside seaworthy 20 or 40 ft containers or in combination to form complete systems with advanced water treatment and purification technologies. Those mobile treatment containers units come with insulation, diamond flooring, LED lighting, climate control, and service hatches. Our mobile or containerized solutions use brackish or seawater reverse osmosis, ion exchange, ultrafiltration systems, multimedia filtration, and MBR technologies, delivered through ocean or inland by trailers.

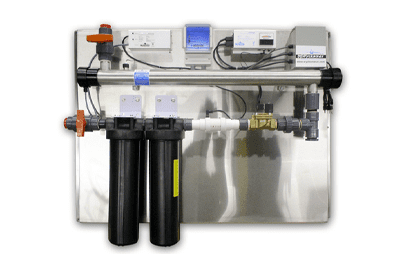

UV water sterilizers utilize germicidal ultraviolet lamps that produce short wave radiation lethal to bacteria, viruses and other microorganisms present in water. Ultraviolet water treatment purification is a unique and rapid method of water disinfection without heat or chemicals. Through the years, ultraviolet technology has become well established as a method of choice for effective and economical water disinfection.

WATERFORCE offers a complete range of chemical feeding pumps. Chemical feeding systems are used in different applications that require mixing, storage, and accurate dosing of particular chemical reagents.

Wastewater treatment plants are built to treat wastewater and cleanse sludge so that each could be returned to the environment. As these plants eliminate suspended solids, contaminants, and organic material from purified water, the oxygen composition is restored. These results are attained through four divisions of treatments named preliminary, primary, secondary, and sludge.

WATERFORCE offers a complete range of Spares & Consumables, which includes RO/NF/UF membranes, cartridge filters & housings, Chemical dosing pumps, FRP filter tanks, Membrane Pressure vessels, Multiport/Control Valves, Membrane Bioreactor Modules, Monitoring & Testing equipments, Filtration Media, Activated carbon & Resins.

The EDI process is a continuous process, utilizes no chemicals for regeneration, does not pollute the environment, and requires a fraction of the operator attention necessary for conventional ion exchange systems. EDI systems typically run between 90 and 95% water recovery. The reject stream is usually of better quality than the feed to the RO system, enabling the reject stream to be completely re-used by pumping it back to the pretreatment section of the RO system. RO/EDI systems may achieve greater than 90% of overall water recoveries by recycling a significant portion of the RO reject stream. All of the EDI reject stream back to the front end of the treatment system.

In the context of water purification, ion-exchange is a rapid and reversible process in which impurity ions present in the water are replaced by ions released by an ion-exchange resin. The impurity ions are taken up by the resin, which must be periodically regenerated to restore it to the original ionic form. (An ion is an atom or group of atoms with an electric charge. Positively-charged ions are called cations and are usually metals; negatively-charged ions are called anions and are usually non-metals).

Usually the main application of ozone in water and wastewater treatment is for disinfection purposes. Ozone is significantly more effective than chlorine at inactivating and / or killing viruses, bacteria and cysts (e.g., Cryptosporidium and Giardia) and has been widely used in Europe for many years to treat municipal drinking water. Ozone’s effectiveness as an oxidant often makes it the method of choice for removing color, organic chemicals and odor-causing contaminants in wastewater. In many cases, depending on the ozone contact time and concentration, it is capable of oxidizing these contaminants to water and carbon dioxide. As examples, toxic herbicides and pesticides may be reduced to more environmentally friendly components; non-biodegradable organic compounds may be reduced to smaller biodegradable parts; proteins and carbohydrates may be lysed at double-bonded carbons to damage and destroy critical components of organisms found in the water.

Automation generally refers to the science and technology of process control and includes the control of chemical and petrochemical plants, oil refineries, iron and steel plant, Power plants, cement mills, Paper pulp and paper mills, water and waste-water treatment plants. PLCs are important building blocks for automated systems. A Supervisory Control and Data Acquisition (SCADA) system means a system consisting of a number of Remote Terminal Units (RTUs) collecting field data connected back to a master station via a communications system.